ITEM SPECIFICS

-

Brand

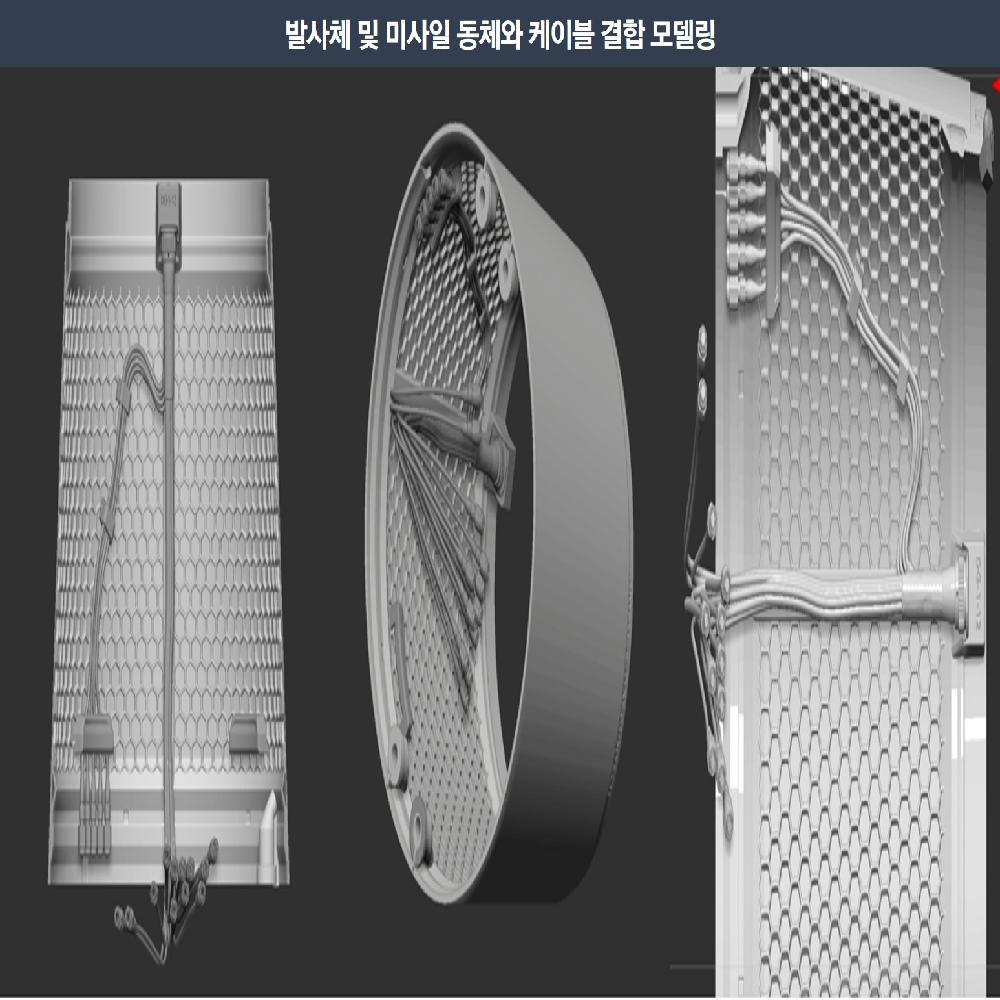

Model DPERTDAEGUN CABLE

-

origin

Republic of Korea

-

Size(Capacity)

Per drawing; envelope up to 800×800×800 mm for printed structures.

-

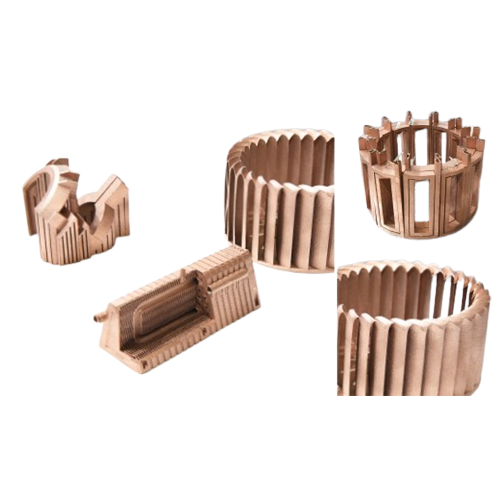

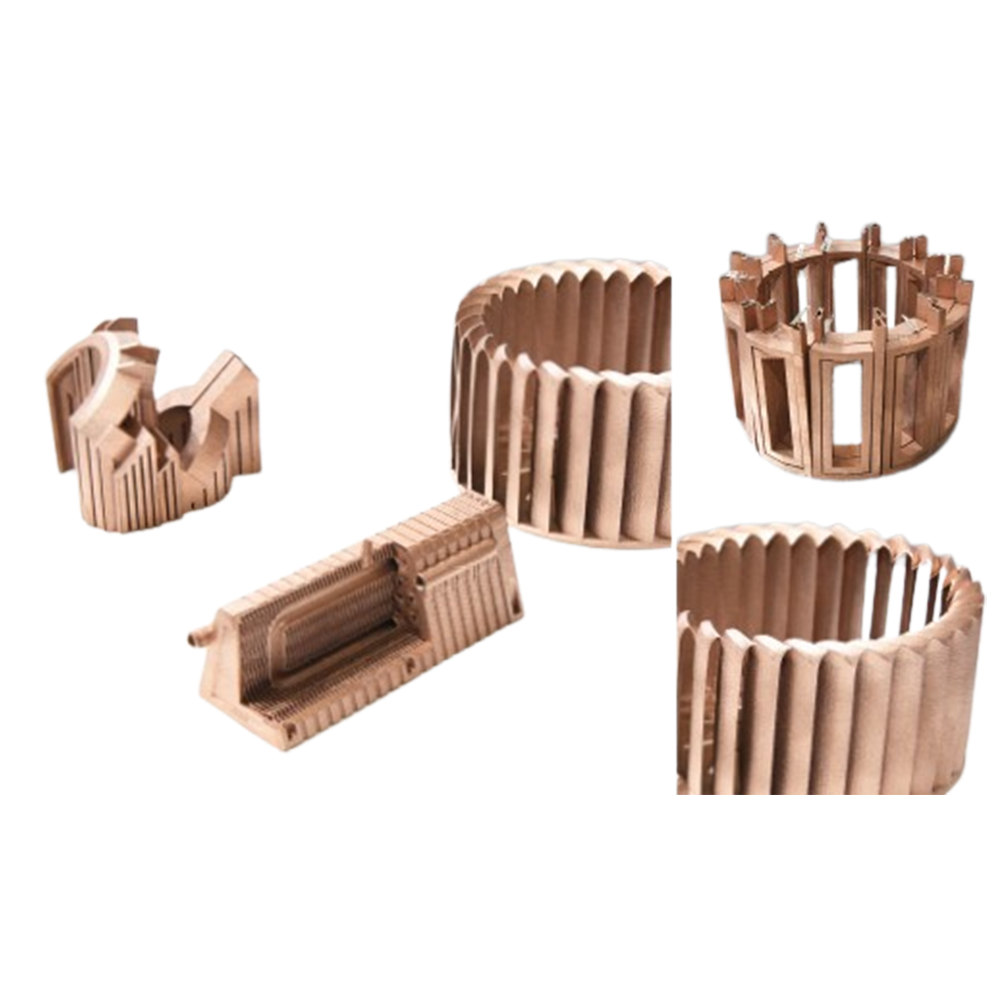

Material

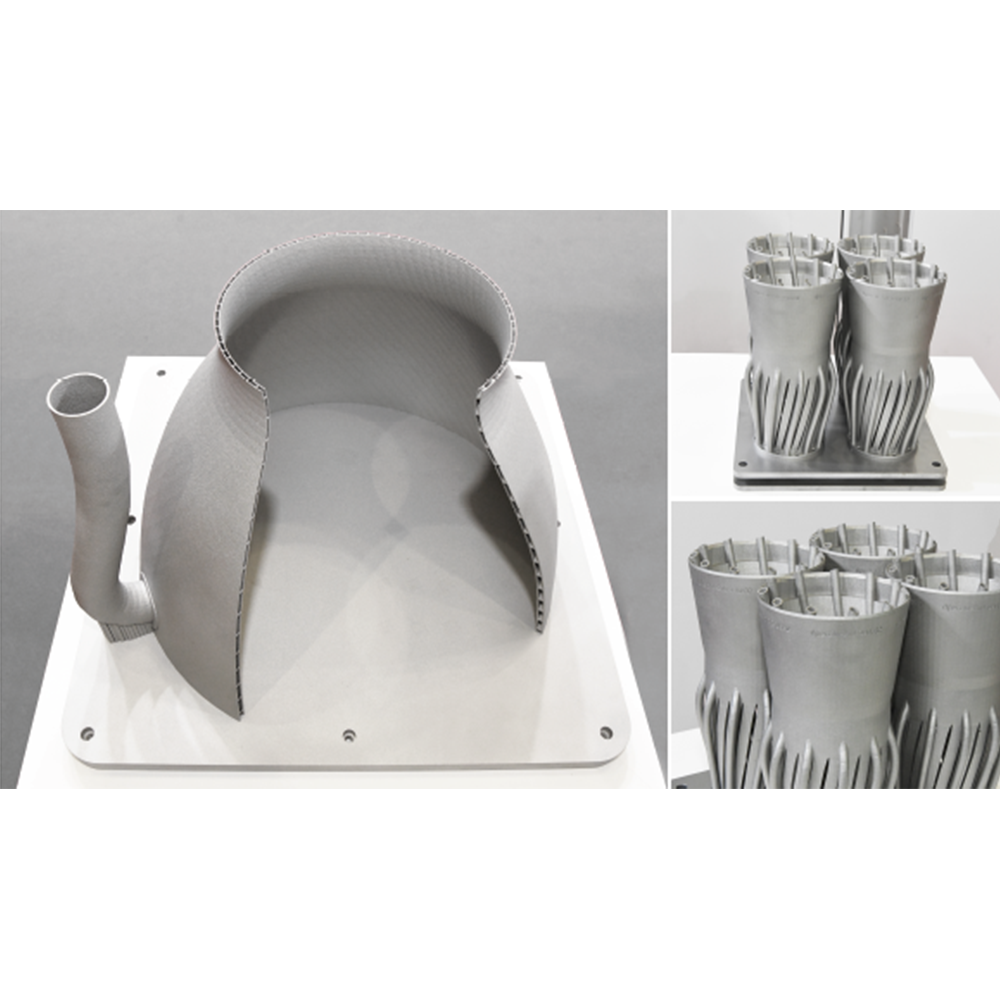

3D-printed metal frames/brackets (Ti/Al/SS/Cu), threaded inserts, PEM hardware, over-mold/backshells

-

Function

Deliver a fully assembled, tested sub-module that integrates printed mechanical parts with wiring

-

Style

Fewer suppliers, shorter lead time, lightweight bracketry with integrated routing

-

Features

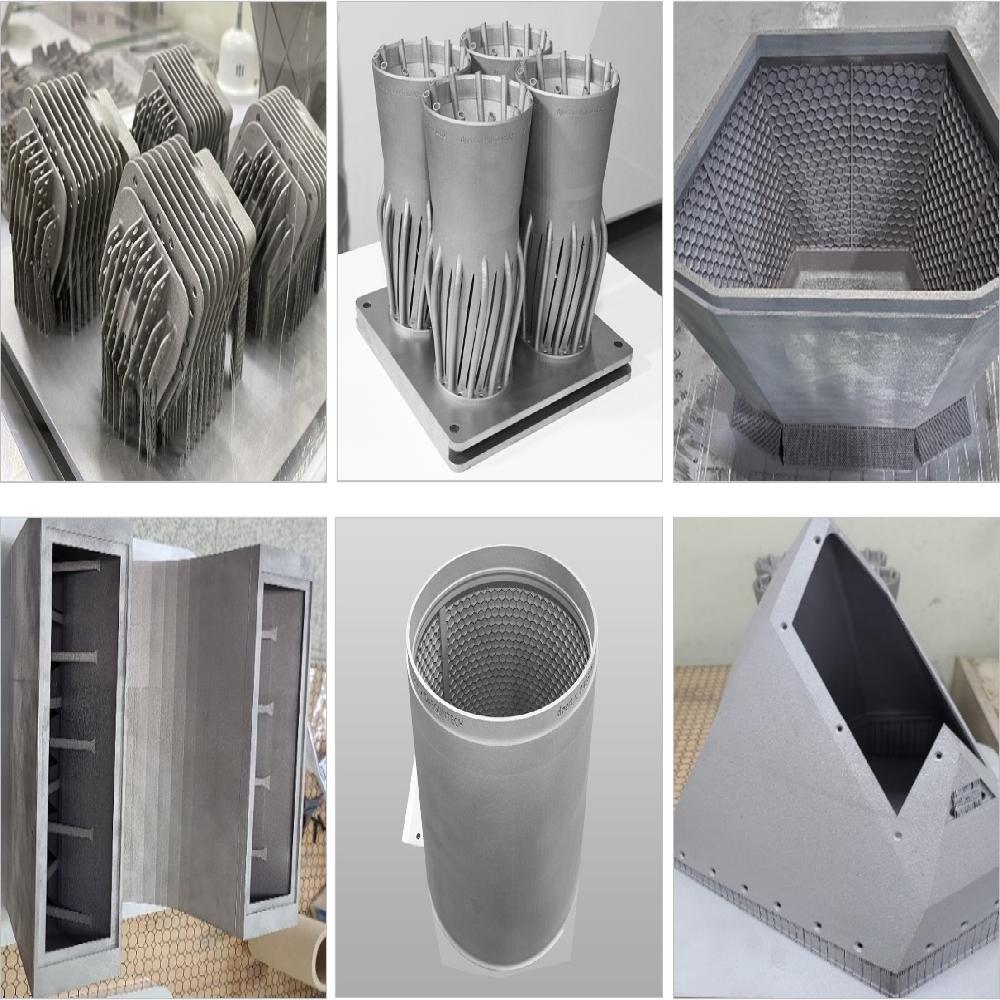

DFM/DFAM co-design, topology-optimized structures, fixture-based assembly, 100% continuity, function

PRODUCT DESCRIPTION

This integrated offering combines our PBF metal printing with harness manufacturing to deliver a ready-to-install electro-mechanical module.

We begin with a joint design workshop to align envelope, mounting points, cable routing and heat/EMI needs. Structural elements—brackets, housings, manifolds or shields—are 3D-printed in aluminum, stainless steel, titanium or copper, then machined, threaded and surface-finished. Harnesses are produced to IPC/WHMA-A-620 standards (Class 2/3), using the specified connector families, backshells and identification scheme.

We create assembly fixtures so that printed parts and wiring mate repeatably, then conduct 100% continuity testing and, when requested, functional tests using customer-supplied jigs.

The build record ties mechanical serials to harness serials for clean traceability; CoC, inspection data and optional FAIR packages can be provided. Integrating printed structures with wiring enables weight reduction and parts consolidation—cable channels, bosses, heat spreaders and attachment features can be built into the metal, reducing separate brackets and fasteners. This shortens your internal assembly time and simplifies logistics to a single deliverable.

Typical prototype modules are completed in 4–6 weeks depending on machining/finish and test scope; production schedules are set by material availability and test capacity.

Final packaging protects both mechanical and electrical interfaces using foam, VCI film and connector caps, with clear labels and a packing list for fast incoming inspection.

With Daegun Tech as a single build partner, you gain a faster path from concept to a validated module that drops directly into your system.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Document against Payment : D/P

- Telegraphic Transfer : T/T

- Name : Dae Woong

SHIPPING

Shipping from :

Republic of Korea

- Sahwa-ro, Uichang-gu, Changwon-si,, Gyeongsangnam-do,, Korea (51389)

DAEGUNTECH CO., LTD.

The person in charge

KI SOO SHINAddress

Sahwa-ro, Uichang-gu, Changwon-si,, Gyeongsangnam-do,, Korea (51389)

Homepage

DAEGUNTECH CO., LTD.

Introduction

DAEGUNTECH CO., LTD. Has been preparing for the future sith stable performance and quality. We are the company which jumps up to be a leading company in the world for the future with outstanding technique and several manufacture experience, and everyone, with one mind, is trying to be the best to each field.

We give thanks to all customers’ support and our outstanding technology, and a variety of manufacturing experience of all employees working hard to become the best in their fields in union.

DAEGUNTECH will further invest on our technology and research and development for better and precise manufacturing to achieve and challenge for new possibilities of exporting our products around the world.

Customer's trust, management transparency, revolution and industrial equipment hardware will take us forward

-

- Business Type :

- Manufacturer

-

- Main Product :

- Metal Additive Manufacturing Cable Harness Assemblies

-

- Established :

- 2004-08-26

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 101~500 people

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 5,716,206

-

- Number of foreign trade employees

- 101~500 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- DAEGUNTECH CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★