ITEM SPECIFICS

-

Brand

Model DAEGUN CABLEDAEGUN CABLE

-

origin

Republic of Korea

-

Size(Capacity)

Per drawing; assemblies packed by sub-bundle

-

Material

High-temp PTFE/ETFE/XL-ETFE wires, shielded twisted pairs, Nomex/Kevlar braids, heat-shrink boots

-

Function

Harnesses for aircraft interiors, avionics, power/signal distribution, defense electronics

-

Style

Class-3 workmanship controls, documentation package (FAI/DMR/CoC as required)

-

Features

Environmental sealing, EMI/RFI shielding, lacing/tie-down per spec

PRODUCT DESCRIPTION

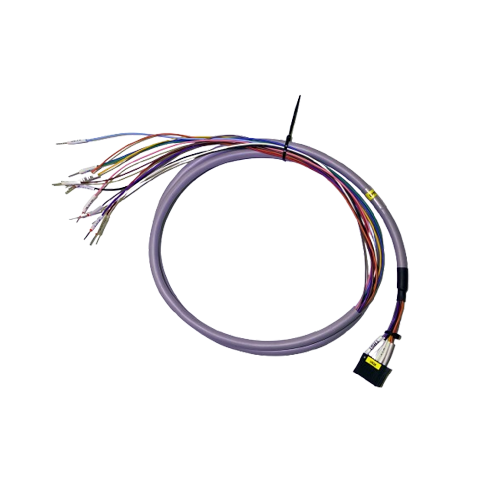

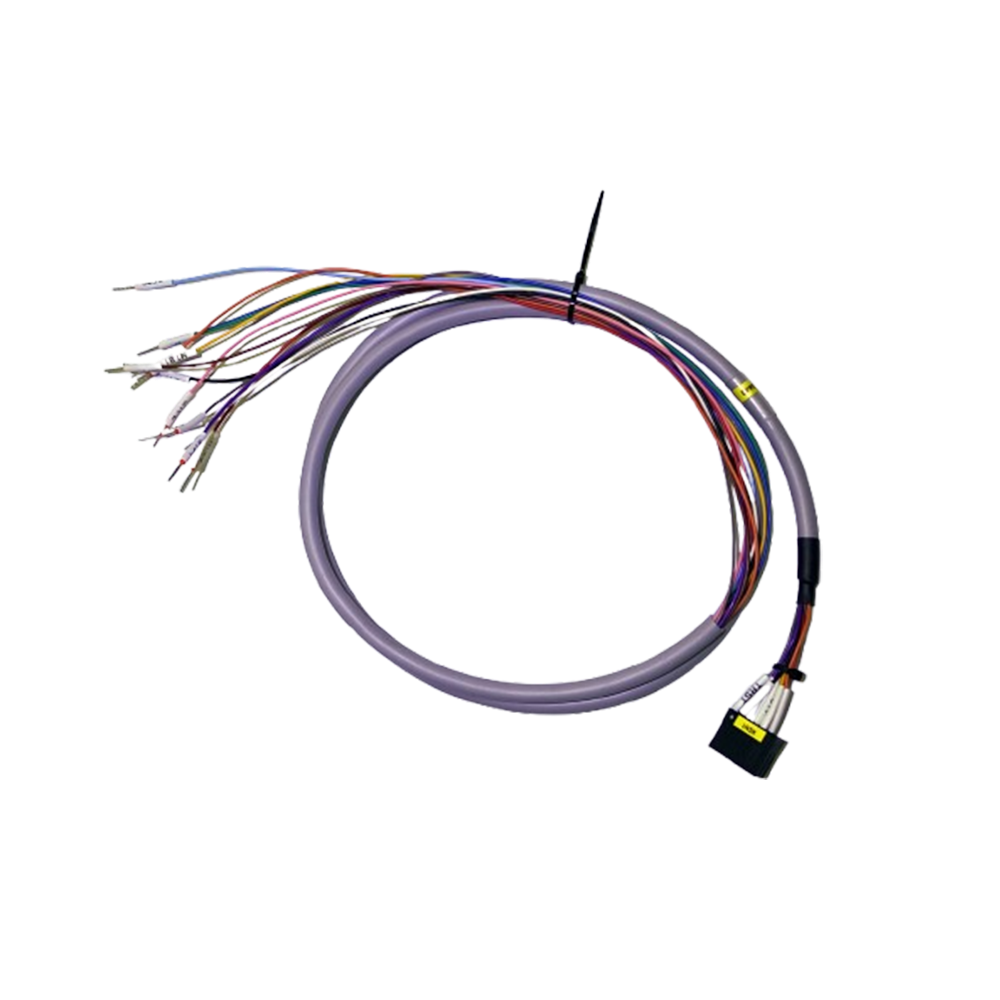

Our aerospace and defense harness service is tailored for flight-quality and rugged applications where reliability and x-documentation matter as much as speed.

We work with high-temperature PTFE/ETFE/XL-ETFE wire families, Nomex/Kevlar lacing, heat-shrink boots and qualified connector systems from Amphenol and Positronic, including backshells and environmental sealing hardware.

During contract review we establish the configuration baseline, test limits and marking scheme, then create build fixtures and inspection checklists to control every operation.

Assemblies are produced under Class-3 workmanship with controlled soldering and crimp processes, shield terminations and strain-relief at all exit points.

Test coverage includes 100% continuity, optional hipot/IR, and functional testing when jigs are provided. Documentation may include DMR, CoC, material certs, FAIR/Delta FAIR, and as-built records with serialization and lot traceability; change control and rework authorization are managed to preserve configuration integrity. Typical use cases include avionics interface looms, power/signal distribution for PSU/CSD systems, cabin electronics, mission equipment and ruggedized ground platforms.

Lead time varies with long-lead connectors and backshells, but we front-load risk with early material reservations and pre-build sub-assemblies where permitted. Packaging follows anti-FOD practices—cap-plugged connectors, protective sleeves, coil wraps and moisture control—then export cartons or ISPM-15 crates. The result is a harness you can install with confidence, supported by the records your program requires and a partner prepared to sustain builds through qualification and LRIP into steady production.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Document against Payment : D/P

- Telegraphic Transfer : T/T

- Name : Dae Woong

SHIPPING

Shipping from :

Republic of Korea

- Sahwa-ro, Uichang-gu, Changwon-si,, Gyeongsangnam-do,, Korea (51389)

DAEGUNTECH CO., LTD.

The person in charge

KI SOO SHINAddress

Sahwa-ro, Uichang-gu, Changwon-si,, Gyeongsangnam-do,, Korea (51389)

Homepage

DAEGUNTECH CO., LTD.

Introduction

DAEGUNTECH CO., LTD. Has been preparing for the future sith stable performance and quality. We are the company which jumps up to be a leading company in the world for the future with outstanding technique and several manufacture experience, and everyone, with one mind, is trying to be the best to each field.

We give thanks to all customers’ support and our outstanding technology, and a variety of manufacturing experience of all employees working hard to become the best in their fields in union.

DAEGUNTECH will further invest on our technology and research and development for better and precise manufacturing to achieve and challenge for new possibilities of exporting our products around the world.

Customer's trust, management transparency, revolution and industrial equipment hardware will take us forward

-

- Business Type :

- Manufacturer

-

- Main Product :

- Metal Additive Manufacturing Cable Harness Assemblies

-

- Established :

- 2004-08-26

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 101~500 people

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 5,716,206

-

- Number of foreign trade employees

- 101~500 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- DAEGUNTECH CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★