ITEM SPECIFICS

-

Brand

Model DG-AM-PARTS (per drawing)DAEGUN CABLE

-

origin

Republic of Korea

-

Size(Capacity)

Per drawing; assemblies packed by sub-bundle

-

Material

UL/CSA wires (PVC/XLPE/PTFE/FEP/ETFE)

-

Function

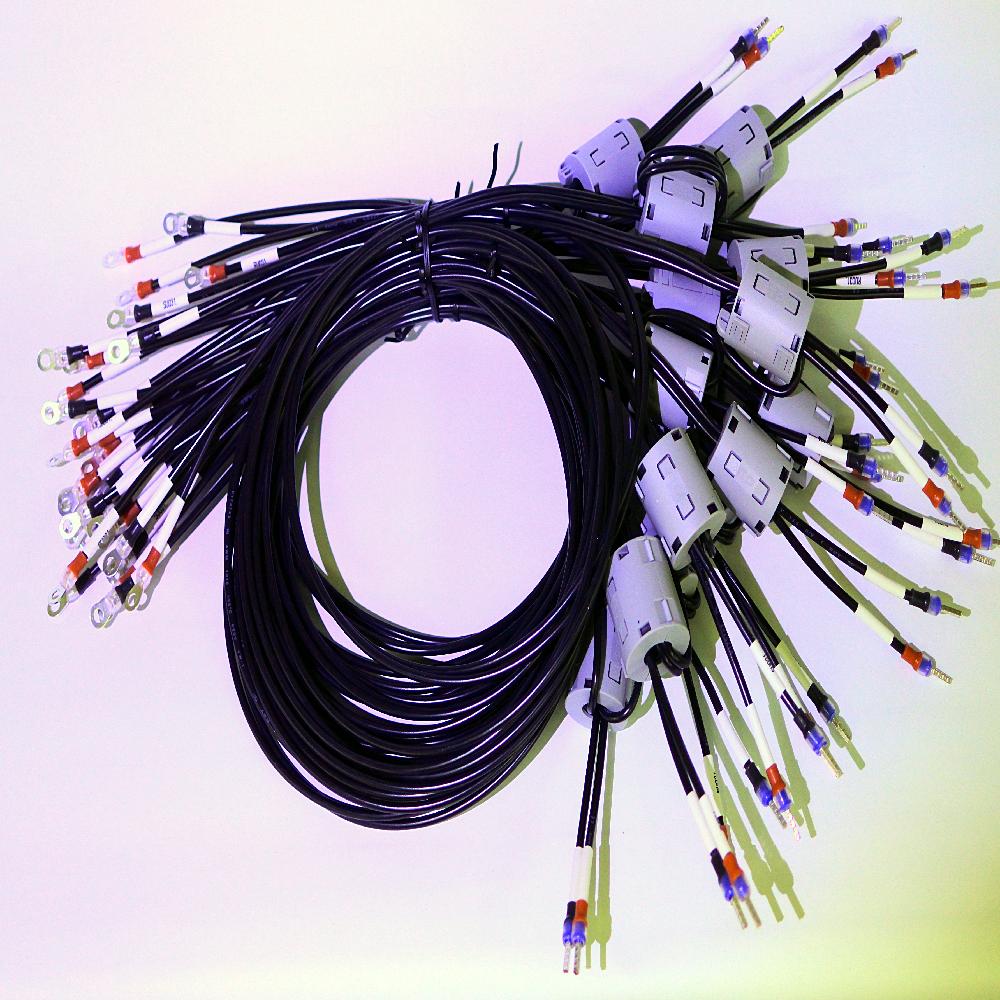

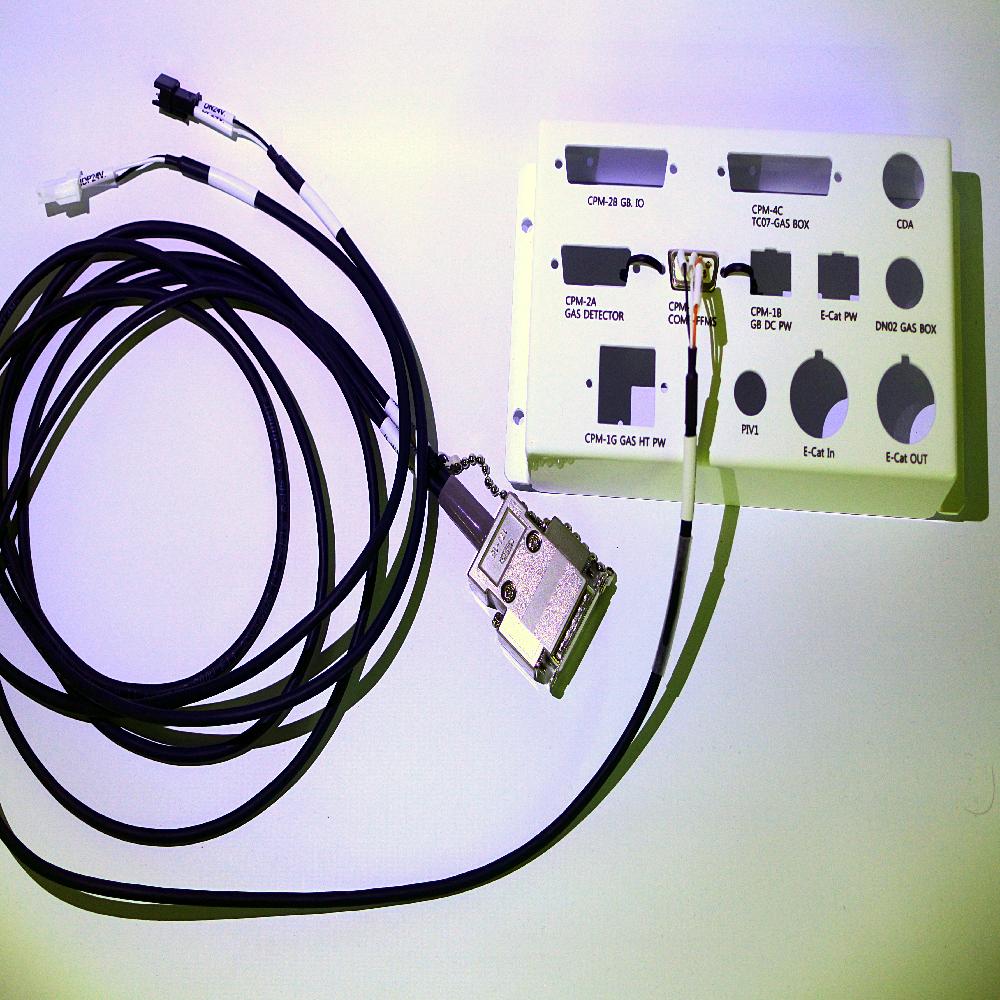

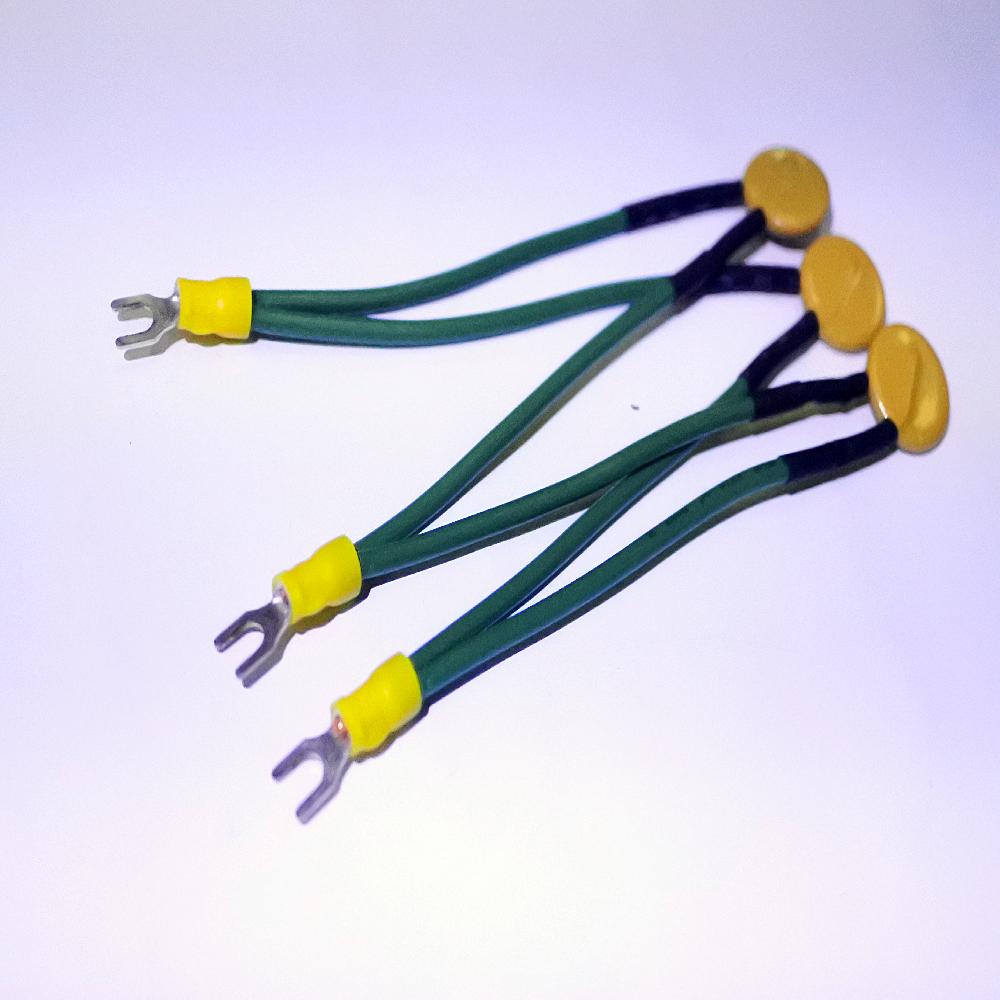

Plug-and-play harness per customer drawing/BOM for automation, semiconductor tools, medical devices

-

Style

Engineering support, rapid prototypes, low-to-mid volume builds, 100% continuity test; RoHS/REACH

-

Features

IPC/WHMA-A-620 Class 2/3 workmanship; crimping, soldering, shielding & braiding, over-mold

PRODUCT DESCRIPTION

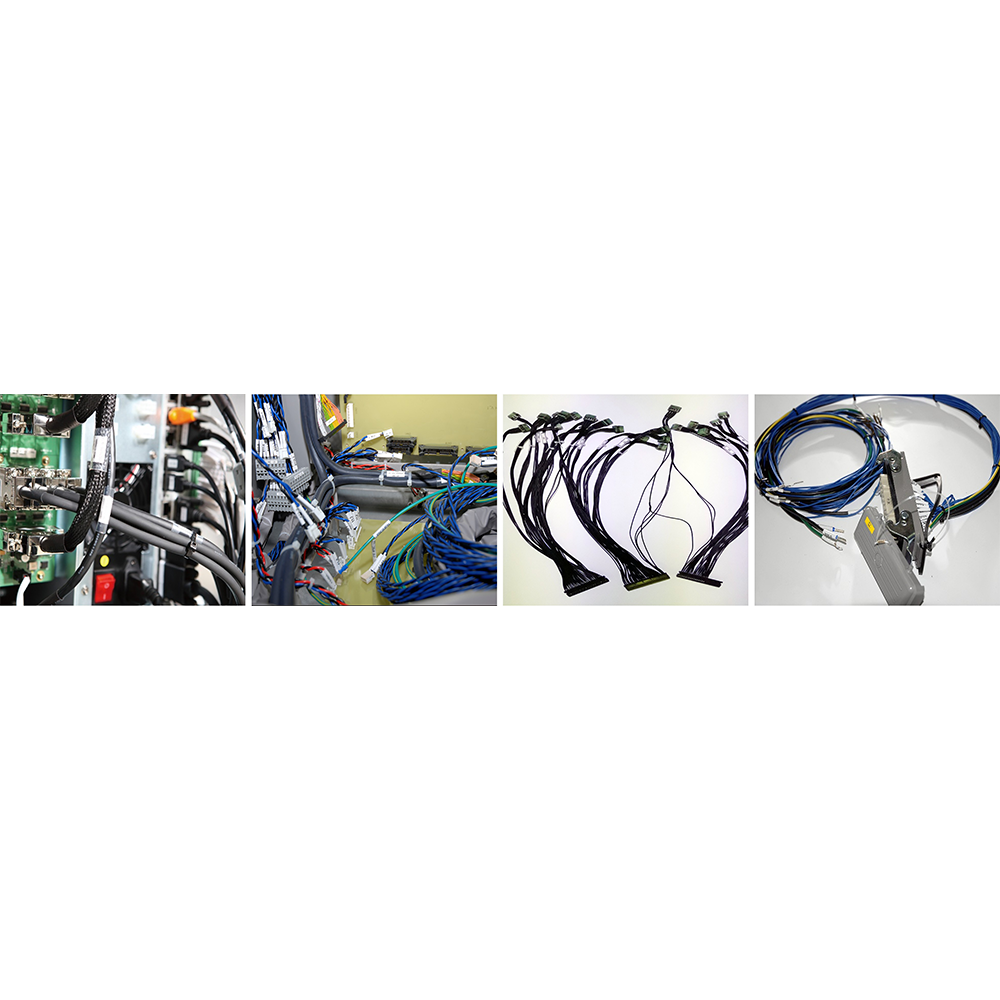

Daegun Tech designs and produces custom industrial wire harnesses for automation equipment, semiconductor tools, medical devices, EV/robotics and general machinery.

Every program begins with a x-documentation review—drawing, BOM and wiring table—followed by DFM feedback on bend radii, strain-relief points, shielding strategy and labeling.

We source UL/CSA compliant wires (PVC/XLPE/PTFE/ETFE) and validated connectors from TE, Molex, Amphenol, HARTING and other ecosystems.

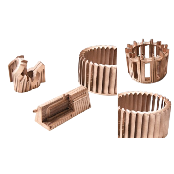

Manufacturing covers cut/strip/crimp with tool validation, soldering for special joints, braid or foil shields, over-mold or backshells, and protective sleeving.

Workmanship follows IPC/WHMA-A-620 Class 2 or Class 3 as required. Electrical testing includes 100% continuity as standard, with optional hipot and insulation resistance tests executed through automated testers and custom fixtures.

For traceability, serial labels and traveler records are maintained, and CoCs can be issued per lot. Prototypes often ship in 2–4 weeks; production releases are typically 4–6 weeks subject to component lead times.

We can kit sub-bundles, provide installation drawings, and pack assemblies by station to shorten your line time.

Finished goods are packed in anti-static bags or coil wraps, cushioned with foam, labeled by harness ID, and boxed in export cartons or wooden crates for long looms.

By combining disciplined quality with flexible MOQs, we help you reduce integration risk while keeping total cost and schedule under control across the entire product lifecycle.

PAYMENTS DETAILS

This supplier supports payments for offline orders

- Letter of Credit : L/C(sight)

- Document against Payment : D/P

- Telegraphic Transfer : T/T

- Name : Dae Woong

SHIPPING

Shipping from :

Republic of Korea

- Sahwa-ro, Uichang-gu, Changwon-si,, Gyeongsangnam-do,, Korea (51389)

DAEGUNTECH CO., LTD.

The person in charge

KI SOO SHINAddress

Sahwa-ro, Uichang-gu, Changwon-si,, Gyeongsangnam-do,, Korea (51389)

Homepage

DAEGUNTECH CO., LTD.

Introduction

DAEGUNTECH CO., LTD. Has been preparing for the future sith stable performance and quality. We are the company which jumps up to be a leading company in the world for the future with outstanding technique and several manufacture experience, and everyone, with one mind, is trying to be the best to each field.

We give thanks to all customers’ support and our outstanding technology, and a variety of manufacturing experience of all employees working hard to become the best in their fields in union.

DAEGUNTECH will further invest on our technology and research and development for better and precise manufacturing to achieve and challenge for new possibilities of exporting our products around the world.

Customer's trust, management transparency, revolution and industrial equipment hardware will take us forward

-

- Business Type :

- Manufacturer

-

- Main Product :

- Metal Additive Manufacturing Cable Harness Assemblies

-

- Established :

- 2004-08-26

-

- Total Annual Revenue :

- More than 10 billion (KRW)

-

- Total Employees :

- 101~500 people

COMPANY ENVIRONMENT

Please suggest a variety of your ideas such as design, impact, enhancements, etc

Captcha Required

Please enter the text on the left image to prevent automatic input.

0 / 4000

질문이 없습니다.

CUSTOMER REVIEWS (0)

TRADE EXPERIENCE

-

- Total revenue

- More than 10 billion (KRW)

-

- Total export revenue (previous year in USD)

- 5,716,206

-

- Number of foreign trade employees

- 101~500 people

COMPARISON TO SIMILAR ITEMS more

- No Items

- supplier level

-

SILVER

SILVER

- DAEGUNTECH CO., LTD. Seller's Store

- Seller's Store url

- Response Level

★ ★ ★ ★ ★

- Supplier Level

★ ★ ★ ★ ★

- Transaction Level

★ ★ ★ ★ ★